Quality Control

We are a Mil-I45208A process control operation, and have implemented a dedicated quality manual (available upon request) that controls the processing of all orders in compliance with the above referenced Military standard. Our quality manual provides us a guideline for not only processing our orders, but also maintaining document control and traceability on all aspects of every customer order.

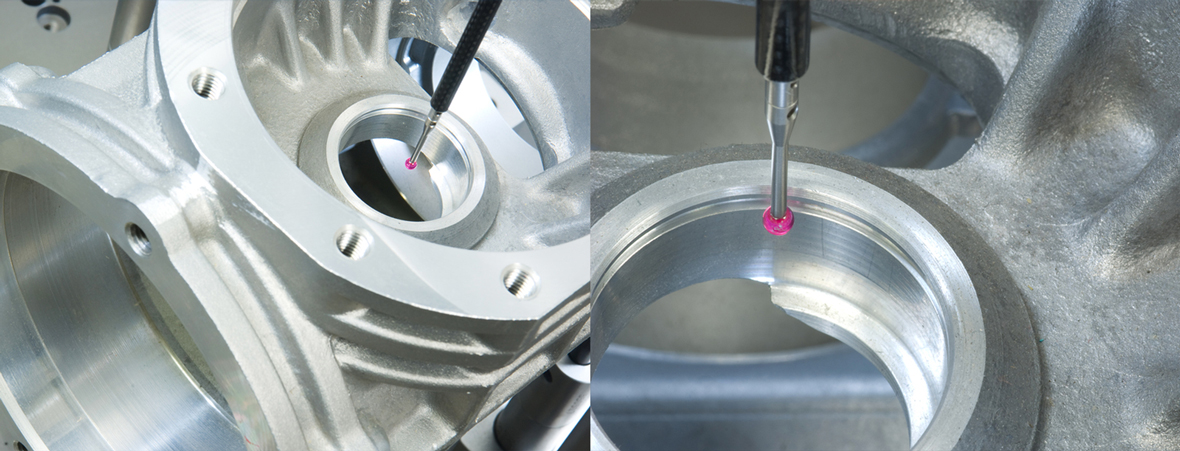

We utilize calibrated inspection tools, which we have serviced and certified by an authorized and National Standards Certified company on an ongoing schedule, according to our quality manual guidelines. We have a coordinate measuring machine, a video microscope, and numerous granite surface plates with height gages, and other gages and tools used in our quality assurance inspections. We document our inspection results in accordance with our quality manual, and as required by our customer purchase orders. We maintain material test reports on purchased raw materials, and require certifications of various procured finishes that are required on the parts being produced for customers.

These documents are maintained on file, and also supplied with all shipments when requested by the customer. We provide our own internal certificate of conformance with every shipment verifying the documents and specifications of each item we produce. We maintain traceability of all job processes for each customer purchase order item, and store these documents for a minimum of 7 years.